- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Methods of Batching Concrete

🕑 Reading time: 1 minuteThe process of measuring ingredients or materials to prepare concrete mix is known as batching of concrete. Batching can be done by two methods, volume batching and weight batching. Batching should be done properly to get quality concrete mix. Contents:Methods of Batching Concrete1. Volume Batching2. Weight BatchingWeight Batching vs. Volume Batching Methods of ...

Asphalt plant process flow

Feb 13, 2017 · The process flow of any asphalt plant will depend on the type of the plant. Right now we have different types of asphalt mixer available in the market. These mixers are build keeping in mind different customer types. There are two major types / egories: batch type and continuous type. Batch type: With this design the production of hot mix ...

Asphalt batch plant by majid

Apr 28, 2015 · Asphalt batch plant by majid 1. INTRODUCTION An asphalt plant is a plant used for the manufacture of asphalt, macadam and other forms of coated road stone, sometimes collectively known as blacktop. Asphalt Concrete mixes made with asphalt cement are prepared at an asphalt mixing plant.

Simem America Corporation | Concrete Mixing Batching ...

Simem America manufactures mixing batching equipment plants for concrete production across industries, including precast concrete, road building, heavy civil construction, and more.

Concrete Batching Equipment | Custom Batch Plant Design ...

Vince Hagan offers a wide variety of concrete batching equipment for any industry. Our engineers can create a custom solution for you. Get a quote today!

Batching Of Concrete Method Statement

Feb 08, 2014 · BATCHING OF CONCRETE. APPROVED BY: QEHS MANAGER. ACTION. Plant: i) Batching and mixing plant shall be pained white and kept clean. ii) If possible, mixing and batching plant shall be shaded from the sun.

How does a concrete batch plant work | Operation of ...

May 25, 2017 · Concrete batching plant process flow will start from the feeding of aggregates into individual bins. Size wise aggregates have to be fed into individual bins. These aggregates will be weighed individually as per the design set in the control panel. After .

Batching Plants | MCT Group

Batching Plants. MCT Group Inc. manages the entire process of design, development, manufacturing and automation controls in the concrete industry. Starting, of course, from the design and engineering of the Batching plants. We provide Tower plants which offer greater storage capacity, extraction, dosing and mixer feeding by gravity; Horizontal ...

How Much Does A Concrete Batching Plant Cost?

The prices of concrete batching plants range between 21,000 and 280,000, depending on the production capacity and the specifiion of the plant you want to buy. Apart from equipment procurement cost, some other outlay, such as setup cost, material purchase cost, maintenance cost, personnel wages, insurance expenses, matter so much that to ...

Role Of Concrete Batching Plant In The Construction ...

Feb 25, 2020 · There are several benefits that the concrete batching plant has to offer to construction workers: · The compact structure in the tailor hanging unit focused on the process of concrete production. · The concrete batching plant occupies small space, and the transfer movement is beneficial. · Concrete batching plants can be controlled manually ...

What Is The Batching Plant Process?

Apr 21, 2020 · A central mixing plant is the other type of batching plant. This plant combines either all or some of the ingredients together at a central place. Water is even included in the mixing process. Different Parts Of A Batching Plant. However, central mix plants differ slightly from ready mix concrete plants because they offer a more consistent ...

Batching Plant | Concrete Machinery | Group

Aggregate Capacity: 3×7 3×10m³. HZS30G. HZS60G. HZS90G. F8 Fast Mounted Concrete Batching Plant. Theoretic Productivity 60 180m³/h. Nominal Capacity of Mixer 1000 3000L. Aggregate Capacity 3×10 4×25m³. Theoretic Productivity: 60 180m³/h.

Concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. In the past, lime based cement binders, such as lime putty, were often used but sometimes with other hydraulic cements, such as a calcium aluminate cement or with Portland cement to form Portland cement concrete (named for its visual ...

How to build a concrete batching plant

Apr 05, 2021 · Though the concrete batching plant uses a fully automated production process controlled by a computer, operators' supervision is indispensable in this process. Therefore, we only need to recruit some experienced concrete plant operators. Camelway concrete batching plant includes standard concrete plant and small concrete plant. The former ...

Concrete Batching Plant Software | Batching Plant Systems

The software controls the batching process of the fibo concrete batching plant with the added benefits of sending all the data from each batch to the cloud database. This means the data is safe, it can be used for automating documentation, improving productivity, delivering live quality control and lots more.

Tips For Maximizing Your Portable Concrete Batching Plants

Jul 27, 2021 · If you are looking for a portable concrete batching plant that will do both lifting and weighing, then an electric control system is probably the way to go. A pressurewasher will require a separate electrical box on site, though this can be done with some prebuilt units. When it comes to weighing, an electric control system is probably the ...

Concrete Mixing Methods and Concrete Mixers: State of the Art

Apr 01, 2001 · Batch mixers are the most common. To determine the mixing method best suited for a specific appliion, factors to be considered include: loion of the construction site (distance from the batching plant), the amount of concrete needed, the construction schedule (volume of concrete needed per hour), and the cost.

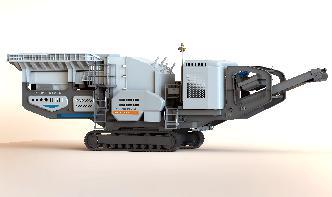

Batching Plant: Types, Advantages Disadvantages

A concrete plant also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form concrete include water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and cement. Batching of concrete could be achieved by either weight batching or volume batching.

Concrete Batching

Concrete batching is generally conducted at plants loed at various strategic positions around a city or town to minimize transport time. Raw materials are mixed in elevated bins and placed directly into concrete trucks for final transport. This process is primarily powered by electricity, with small amounts of other fuels used on each site by small excavators used to move raw materials, etc.

Sustainable Concrete Construction

Batching of concrete is one of the affecting factors. Electric power is used to mix components of concrete in a high placed container in addition to small amount of fuel consumed by small trucks used to move materials ; CO2e/m 3 emission is produced due to batching/m 2 .

Copyright © .CMichineAll rights reserved.خريطة الموقع