- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Teknologi Semen | Arpumiko's Weblog

Jul 16, 2010 · 1. Eisen portland cement Yaitu semen yang dihasilkan dari penggilingan campuran 60% terak portland dan 40 % butirbutir slag tanur tinggi. 2. Hogh Ofen Cement Semen yang dihasilkan dari penggilingan campuran yang mengandung 15 – 19 % terak portland cement dan 41 – 85 % butir –butir slag dengan penambahan CaSO4. Pustaka: (A) Anonim. 1980.

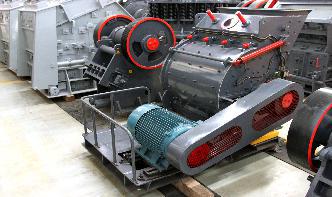

Tahap penghalusan semen(cement grinding)

Nov 22, 2017 · Bentuk Cement Mill atau Finish Mill seperti gambar di atas. Sebelum digiling, biaa komposisi Klinker ditambah oleh bahanbahan tambahan seperti Gipsum, Pozzolan, Trash dan lain yang lain nya. gambar gipsum. Setelah halus, klinker ini berubah namanya menjadi hasil akhir yaitu semen.

fungsi utama rolling compression mils

Fungsi Utama Rolling Compression Mils Primary Jaw. Fungsi Roller Mill czeueu fungsi rolling mill impact mining equipment small fungsi utama rolling compression mils Mining World Quarry ball mill hammer mill roller mill machine manufacturer of high 0 019 dia micro carbide ball mill .

what is finish mill of a cement process | Mining Quarry ...

Apr 02, 2013 · Concrete Stamp Roller – Information and pictures on how to get a rocksalt concrete finish without using actual salt particles. ... Cement equipment manufacturer supplies cement plant machines:stone crusher, cement mill, ball mill for cement processing in cement grinding plant.

trunnion bearing on cement mills

finish mill trunnion shaft. cement ball mill maintenance trunnion bearing. End walls for ball mills with trunnion bearings. to know what we can . Sheet – French Cement Ball Mill ... ©SKF Slide 1 SKF Mining, Mineral Processing Cement.

Filter Bag for Cement Plant – Filmedia Home

Filter Bag for Cement Plant. During cement production process, there is a lot of dust and gas emissions outwardly, there are many different filter bags can be chosen for meet varied working condition. Capacity: 2000 pcs per day. Main Material: Fiberglass, Nomex, P84, PTFE needle felt. Finish Treatment: Singeing, Calendering, Heat Setting, Anti ...

Shower Curtains Accessories | City Mill

Add to Shopping List Add to Compare. InterDesign 43 in. 75 in. Medium White Finish Stainless Steel Cameo Constant Tension Rod. InterDesign. Quickview. Add to Shopping List Add to Compare. 43 in.75 in. Brushed Stainless Steel Astor Shower Curtain Tension. Quickview.

CASE STUDY

Cement setting times; Cement water demand (at a constant workability) * SSA is the specific surface area (m 2 /kg) of the finished cement (final product). CLOSED CIRCUIT MILL ‑ ANSWER. i) Lower mill exit surface area means lower fineness in the mill itself and so less tendency for agglomeration, coating, over grinding, cushioning etc.

cement mill notebook ball charging

Cement Ball Mills Charging. Ball charging process in cement mill davyroelstraetebe ball mill media charging clinker grinding ball mill media charging process the ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powder making production line including cement silie newtype the rotation of the ball mill causes the charge.

Djoko Metran Dinata

Finish Mill CRO Cement Plant ( CEMENGAL Ball Mill ) PT Cemindo Gemilang (Semen Merah Putih) Feb 2019 Saat ini 2 tahun 5 bulan. Mini Grinding Plant, Kampung Melayu, Bengkulu, Indonesia 38215 Main Tasks Responsibilities : • Works for company safety standards and legal requirements. ...

the maxecon mill for finish grinding of cement

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Finish Mill Of Cement Plant

Finish Mill Of Cement Plant . Finish Mill Process Of Cement Feilloos Leven. Cement finish mill process . Cement finish mill process. Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete panies to be used in a variety of construction projects Although the dry process is the most modern and popular way to ...

Emission Testing Report, ETB Test Number 71MM06 ...

EMISSION TESTING REPORT ETB TEST NUMBER 71MM06 Emissions From Wet Process Clinker Cooler And Finish Mill Systems at IDEAL CEMENT COMPANY HOUSTON, TEXAS Project Officer Clyde E. R1ley ENVIRONMENTAL PROTECTION AGENCY Office of A1r Programs .

finish mill of cement plant

Finish Mill Atau Cement Mill . lump mineral merk atau type jn made in america amp ensp 183 amp ensphow install cement mill trunnion gb rtd Grinding Mill China Results 1 18 of 18 A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that .

finish mill of cement plant

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills

cement manufacturing

Cement grinding. The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement. Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm).

Galih Purwanto

Indocement P34 Finish Mill Project ... Scope of Project Cement Mill and Finish Mill Tender Result: Won Indomarine PLTSa DCS Project Mar 2018 Jul 2018. Technical Design and Proposal making for the PT. Indonesia Marine PLTSa Bantar Gebang DCS Project. ... Tingkat fasih atau penutur asli

PENGELOLAAN INDUSTRI SEMEN dan PROSES PEMBUATAN .

Oct 15, 2015 · Sehingga dengan kemampuan grinding mill yang sama dengan ditambahkan Dust Return, maka volume pada produksi semen PPC makin meningkat. Peningkatan kapasitas ini sebelum penambahan dust return kapasitas mill Ton/t a h un dengan adanya invensi ini kapasitas mill menjadi Ton/t a h un.

Process

Early models were not very reliable.) Internal Water Sprays in Ball Mills Most cement finish mills employ some type of internal water spray to control mill discharge temperatures. Through proper control of the mill internal temperatures the operator influences: a) Gypsum dehydration which impacts false set performance (or in isolated cases ...

Proses Pembuatan Semen | Maulana's Blog

Dec 28, 2012 · Secara overall proses pembuatan semen ada 4 tahap Raw material preparation Burning/clinkerization Cement/finish grinding Packing dispatch Berikut adalah uraian tiap tahapan di atas 1. Raw Material Preparation Tahapan ini sendiri terdiri atas beberapa step yang meliputi mining (penambangan), crushing, preblending, raw material grinding, dan raw meal blending A. Mining Mining .

Cement Finish Milling (Part 1: Introduction amp; History)

Dec 02, 2019 · The finish mill system in cement manufacturing is the second to last major stage in the process, where the feed material is reduced in size from as large as several centimeters in .

CALPORTLAND® ANNOUNCES COMMISSIONING OF NEW FINISH MILL .

Mar 26, 2019 · Glendora, CA, March 26, 2019 (GLOBE NEWSWIRE) CalPortland announces the commissioning of a new finish cement grinding mill and distribution system at its Oro Grande, CA cement .

Cement mill

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Copyright © .CMichineAll rights reserved.خريطة الموقع