- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Infrared Drying

• salt, coal, gravel, sand, ore, coke, coke briquette, agglomerate ore fines; • and much more, including a variety of custommade products and lump materials. Features and benefits Due to the peculiarities of the technology, infrared drying has enormous advantages over conventional drying methods.

coal crusher milling drying

coal crusher milling drying. A leader in mining crushing equipment, specializing in the production of crushers, mills, and sand making machines.

How to Remove Pyrite from Coal

Jan 14, 2021 · Conventional wetwashing methods effectively remove liberated pyrite down to fine size; however, to liberate the finesize pyrite, additional crushing of the coal below transportation size is necessary. If these finesize coals are cleaned by wet methods, problems of coal drying and wetwaste disposal are introduced.

coal making process plant

coal preparation plant process and equipment for coal. Mar 27, 2019 · The equipment and process of the coal washing plant are related. The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the sorting operation, and the processing of the selected products

(PDF) Crushing properties of coal

The Hardgrove grindability index HGI is closely related to the power consumed in crushing coal and may be used to optimize crushing in the coalpreparation shops at coke plants, as shown in [1] [2 ...

50 tph coal slurry dryer machine for sale in jharkhand

The coal ash dryer made by our, as the Chinese leading raw coal drying machine supplier, is specialized in drying the coal ash . offers 245 coal sludge dryer products. About 21% of these are Rotary Drying Equipment, 1% are Drum Drying Equipment. A wide variety of coal sludge dryer options are available to you, such as warranty ...

Appendix E: Coal Mining and Processing Methods | Coal ...

Coal drying. Coal preparation plants that employ fine coal cleaning by froth flotation can produce an unacceptable amount of moisture in the product. Thermal drying, in which the wet coal is dried in the hot gas generated by a coalor gasfired burner, is used in some plants to reduce the moisture content. Refuse and tailings management.

Coal washing | Coal preparation | Coal washing plant pcocess

Apr 10, 2019 · According to different screening methods, it is divided into dry screening and wet screening. 3. Coal crushing. In coal preparation plants, the crushing operation should be adapted to the requirements of the selected particles; in order to select the fine baking from the coal, the crushed coal should be broken into smaller particles to separate ...

Coal Slime Dryer in Coal Drying Production Plant sorata ...

Oct 22, 2012 · Coal slime dryer take the new technology that breaks the coal slime, and then dry it by heat, the disposal of the coal slime reaches the continuous urbanization, industrialization and automation. After drying process, the water content of slime can be decreased from 28% to 12%. Coal Crushing Plant with 1000 tons per hours

Coal Sample Preparation Procedures Overview | TopSampler

Jul 02, 2018 · Normally, coal sample drying should not exceed 50 degrees centigrade and dry on the floor will take much longer than in the drying oven. After continuous drying, the mass change of coal samples should not exceed %, and we should cool coal samples at ambient temperature and balance them with atmospheric humidity.

Best Coal Drying Technique In Rwanda

Best Coal Drying Technique. 9 1 Introduction Peat has been used as a form of energy for at least 2 000 years It was useful as an alternative to firewood for cooking and heating in temperate and boreal regions of Europe in particular Ireland England the Netherlands Germany Sweden Poland Finland and the USSR The increasing use of gas and oil as cooking and 06 2020 Lately microwave ...

why choose the mobile crusher in coal crushing plant ...

Aug 21, 2020 · Speaking of coal shredders, many people in the industry may think of doublestage shredders or jaw crushers. Indeed, whether it is an underground coal mine or an openpit coal mine, these equipment can adapt to the coal mine environment to stably carry out crushing operations. However, in the long run, coal resources are widely distributed.

Coal Slime Dryer_HENAN YUHONG HEAVY MACHINERY CO.,LTD.

4. Coal slime drying machine system using the new type feed, discharge device. Put an end to the drum dryer feed plug, not continuous, uneven and returning materials, and so reduce the load of dust removal system. 5. New internal structure strengthens the cleaning of distributed material and heat conduction, eliminates the sticky phenomenon of ...

Coal Milling And Drying Process

fendsenry Coal mill process | Coal mill process. Coal is mined by explosion, then crushed by coal crusher into tiny change the gap from the grate bar from 25mm to 22mm; therefore decrease the wind speed and raise the drying speed . three. add a settling chamber among the coal mill and also the pipe; for this reason...

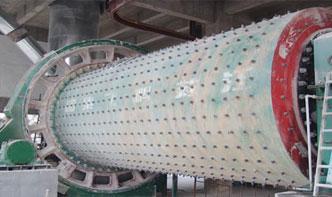

Coal preparation plant

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Coal Handling Plant Layout | Thermal Power Generation Station

May 13, 2020 · Methods of Coal Storage . The coal can be stored by using one of the following methods to reduce the chances of oxidation and combustion : Stocking the coal in heaps; Underwater storage; 1. Stocking the Coal in Heaps. Following steps are used while stocking the coal in heaps: The ground used for stocking the coal should be dry and level.

USB2

A waterless method of processing coal to remove impurities therefrom includes drying a batch of coal to remove moisture therefrom, pulverizing the coal into individual coal particles to liberate impurity particles from the coal and without substantially reducing the size of the impurity particles, and separating the impurity particles and pulverized coal particles into respective product ...

Copyright © .CMichineAll rights reserved.خريطة الموقع