- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Hydrothermal phase transformation of hematite to magnetite ...

May 13, 2014 · The more stable phases in iron oxides are hematite and magnetite. Hematite can be used in a lot of appliions, such as sensors [], water photooxidation [], drug delivery [], lithium ion battery [], pigmentation [], solar cell [], etc., and magnetite can be utilized in biomedicine [7–11], magnetic devices [],, studies about the nano/microstructures of iron oxides and their ...

Hydrogen Reduction of Hematite Ore Fines to Magnetite Ore ...

Surplus coke oven gases (COGs) and low grade hematite ores are abundant in Shanxi, China. Our group proposes a new process that could simultaneously enrich CH 4 from COG and produce separated magnetite from low grade hematite. In this work, lowtemperature hydrogen reduction of hematite ore fines was performed in a fixedbed reactor with a stirring apparatus, and a laboratory Davis magnetic ...

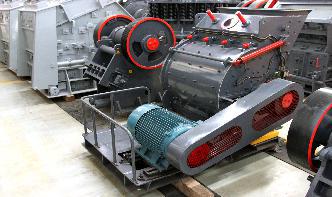

Hematite Separation Process

Hematite Separation Process . Process Introduction. The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved.

Iron Ore Mining | Techniques | Metal Extraction

The iron ore, coke and limestone are crushed into small round pieces and mixed and put on a hopper which controls the input. The most common ores of iron are hematite Fe 2 O 3, and magnetite, Fe 3 O 4. These ores can extract iron by heating them with the carbon present in the coke. Heating coal in the absence of air produces coke.

hematite iron ore

Mar 30, 2021 · Common hematite iron ore beneficiation processes include froth flotation, magnetic separation, gravity separation and roasting process, which means that the raw ore enters the separation process after passing through the crushing and screening, grinding and classifying stages, and the hematite concentrate is separated by flotation equipment, magnetic separation equipment and gravity .

Extraction of Iron Concentration of Ore

Sep 23, 2019 · Most of the molten iron from a Blast Furnace is used to make different types of steel. Calcination is the process of converting ore into an oxide by heating it strongly. The most important iron ore is hematite. The iron extraction process is a long process which begins with calcination and then followed by a few major steps.

Difference Between Magnetite and Hematite | Compare the ...

Jan 28, 2012 · Magnetite iron is in +2 and +3 oxidation states whereas, in hematite, it is only in +3 oxidation state. This is the key difference between magnetite and hematite. Moreover, magnetite has higher iron content than hematite; therefore, its quality is higher. Apart from that, in colours too, there is a difference between magnetite and hematite.

How to Process Hematite: Beneficiation Methods and Project ...

May 27, 2021 · Hematite, weakly magnetic iron ore with better floatability than magnetite and wide distribution, is one of the most important raw materials for ironmaking.. Its composition is complex. In addition to containing a small amount of magnetite, the impurity embedding of hematite has uneven particle size and high content of fine particles, which often requires some beneficiation processes.

Labrador Iron Mines Holdings Limited :: Iron Ore Products ...

Hematite has in the past been referred to as natural ore because certain hematite ores contain up to 69% iron and can be directly fed into blast furnaces in the steel milling process. Hematite ore also lends itself to the beneficiation process unlike lower grade magnetite, and is .

Hematite

Hematite is a natural resource in Astroneer. Hematite is made of reddishblack, crystalline spikes. 1 Source 2 Uses 3 Trivia 4 Media Hematite can be found on the following planets: The Trade Platform gives 2 Hematite for every 3 Scrap, up to 4 total for 6 Scrap. Hematite is used to craft the following items: The primary ores of iron are hematite, limonite, magnetite and siderite, with hematite ...

Hematite Information

May 19, 2020 · Hematite is an iron oxide mineral which is technically made up of 70% iron and 30% oxygen (though rarely found that pure). Its usual appearance is a silver to dark gray, smooth gemstone cut into variously shaped cabochons and very rarely faceted.

Optimization of the Iron Ore Direct Reduction Process ...

Iron ore direct reduction is an attractive alternative steelmaking process in the context of greenhouse gas mitigation. To simulate the process and explore possible optimization, we developed a systemic, multiscale process model. The reduction of the iron ore pellets is described using a specific grain model, reflecting the transformations from hematite to iron.

USA

materials Substances description 18 US195842A Process for the manufacture of hematite cast iron Expired Lifetime USA ( en )

Metaphysical guide of Hematite, Physical properties of ...

A recently developed process, magnetation, uses huge magnets to glean waste hematite from old mine tailings in Minnesota`s vast Mesabi Range iron district. Hematite on Mars: The spectral signature of hematite was seen on the planet Mars by the infrared spectrometer on the NASA Mars Global Surveyor ("MGS") and 2001 Mars Odyssey spacecraft in ...

Different Types of Iron Ore

Oct 05, 2016 · The iron minerals that are at present used as ores are hematite, magnetite, limonite, and siderite; also, occasionally ankerite, goethite, and turgite. Hematite is the most important iron ore. The iron content of the pure minerals is as follows: Ankerite is a carbonate of lime, magnesia, manganese, and iron.

What is the process for polishing hematite? How does it go ...

"Almost any metal or hard plastic item can be buffed to a high polish or a satin sheen with the correct buffing wheel and the proper polishing compound. This includes copper pots, doorknobs, golf clubs and switch plates, to name a few common items...

Hematite | Rock Gem Magazine

May 30, 2019 · Hematite crystals atop cubic crystals of bixbyite, found in Maynard's Claim, Thomas Range, Juab Co., Utah. (WIKIMEDIA COMMONS) Hematite (Fe2O3) is the most common and most important of the several iron oxides. It forms lovely shiny black hexagonal crystals that can be clustered like the petals of a flower.

Copyright © .CMichineAll rights reserved.خريطة الموقع