- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

How to choose a mining screen? Roller screen and vibrating ...

The vibrating screen is mainly composed of a screen box, a screen frame, a screen mesh, a vibrating motor, a motor base, a vibration damping spring, and a bracket. Linear vibrating screen: Two vibrating motors are installed at the bottom of the equipment, which can be divided into several layers.

38 Vibrating screen ideas | screen, henan, conveyor

Mar 19, 2016 Explore wong's board "vibrating screen" on Pinterest. See more ideas about screen, henan, conveyor.

A Guide to Dewatering Screens: Everything You Need to Know

— The goal of dewatering screens is to deliver the cleanest possible filtrate and driest possible solids. — Dewatering screens use a relatively simple mechanism to filter materials. — There are several factors to consider when choosing the most suitable dewatering screen mesh size and design.

vibrating screens dimensions

How To Choose Meshes Dimensions On Vibrating Screens. The Factors Affecting Double Deck Vibrating Screen. The properties of material on double deck vibrating screen. The material size is smaller than the 3/4 of mesh size ...

Mosquito Wire Mesh Types and Benefits

May 04, 2021 · Micro Mesh India Pvt. Ltd. is one of the leading manufacturer of wire mesh. MICRO MESH, established in 1996, is one of the largest wire mesh manufacturers in india and stockist of industrial wire cloth, screen meshes and mosquito mesh/insect screens in stainless steel,, copper bronze, aluminium etc. Contact us now for any kind of wire mesh requirements today.

Window Screen Mesh Types Explained

The most commonly used window and door screening for new construction and replacement window screens. Charcoal color is the most popular as it has the best outward visibility. Available in Charcoal and Silver Gray colors. Mesh: 18 x 16, Diameter: .011. Charcoal Fiberglass. Insect Screen. Silver Grey Fiberglass. Insect Screen.

Stainless Steel Round Ultrasonic Vibrating Screen for ...

Ultrasonic vibrating screener can convert the 220V,50HZ or 110V,60HZ electric energy to 18KHZ high frequency electric energy, then, convert it to mechanical vibration of 18KHZ through ultrasonic generator and transmit to the screen mesh. The superfine powder on the screen mesh will get greater ultrasonic acceleration and avoid a series of ...

vibrating screens size

size of net vibrating screen size of net vibrating screen_TECHNICAL NOTES 4 VIBRATING SCREENS mineraltech MODSIM ModsimTraining Module3 VibratingScreens pdf4 . Inquire Now; different mesh size rotary vibrating screen machine. different mesh size rotary vibrating screen machine .

Ultrasonic Vibrating Sieve/Screen

Ultrasonic vibrating screen keep the screen mesh size, screening accuracy stably, reducing the number of repeated screening. The electric power of 220V and 50Hz is converted into 36KHz mechanical vibration, so as to achieve the purpose of efficient screening and cleaning the mesh, which make the ultrafine powder screening to be easy.

How To Choose Suitable Vibrating Screen

Jan 09, 2019 · 1. First of all, we must determine whether the materials we are screening are roughly sieved or finely sieved; if it is roughly sieved, we can choose equipment such as linear vibrating screen and circular vibrating screen, which has large output and high efficiency; if it is fine screening, you can choose equipment such as rotary vibrating screen or ultrasonic vibrating screen.

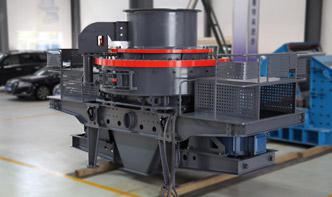

Circular Vibrating Screen – Cement Vibrating Screen For ...

Circular vibrating screen, also known as circularmotion vibrating screen and singleshaft vibrating screen, is a new type of vibrating screen machine, which can screen coarsegrained materials by circularmotion is widely used in the mining industry, building materials industry, energy industry, chemical industry, and other industries.

China Linear Vibrating Screen for Plastic Particles ...

When the linear vibrating sieve machine starts to work, two vibration motors installed on the equipment work simultaneously but in reverse the vibrating force and gravity, the materials are thrown up on the sieve and pushed forward to make a straight movement. Materials smaller than mesh size will pass and are collected to achieve the classifiion.

Vibrating Screen_Vibrating Screen_Mining ...

When choosing the material for manufacturing screen deck, these factors are very important to consider,such as corrosion, abrasion, heat, vibration and weight etc. We weave the screens in stainless steel or high tensile steel. High tensile steel . Vibrating screens or quarrying screen exert a great strain on screens,the high tensile wire's ...

different types of wire mesh vibrating screen

A wide range of Vibrating Screen, Wire Mesh Vibrating Screen and High Frequency Vibrating Screen made of high grade metals is available to fulfill varied requirements of industries. We have screens in different materials, wire diameters, mesh opening, dimensions and weaving patterns that can be chosen as per the specific.

how to vibrating screen

How to choose vibrating screen Henan Pingyuan Mining Machinery Co., Ltd. ... Round vibrating screen is widely employed in mineral processing for screening different size ore. It plays an important role in the whole processing line. So correct operation and maintenance get price.

Selection Standards for Mining Vibrating Screens | Hawk ...

Jan 30, 2018 · A quick look at a highvolume panel shows off the wiremesh architecture. Again, a formula dictates the mesh size and layout. That bythenumbers theorem uses the aperture dimensions, wire mesh count, and wire diameter to create a standard wire gauge product line, one that operates at the micron scale, all the way up to the centimetre range.

How to select dewatering screen for sand plant? | LZZG

The auxiliary screen with larger mesh size is used for prescreening. According to the difference between fine screening and rough screening, the suitable dewatering screen is selected. For rough screening, you can choose dehydration screen such as linear screen; for fine screening, you can choose dehydration screen such as rotary dewatering ...

How To Size Screens For Vibrating Screens

Vibrating Screens can be operated either with counter flow or conveying actions with a wide range of mesh sizes and types of screen meshes High Speed DOVE Vibrating Screens can be operated at high speeds to ensure maximum screening is an important part of processing and is used to separate material according to its size ...

Midwestern Industries | Sifting Screens Distributor

Screens Screens to fit most makes and models of separators. Aftermarket Parts Motors, clamprings and much more. Immediate shipping is available on most items. Wire Mesh Screens Made to Last Midwestern weaves our mesh and makes our panels to fit most screening machines.

What are good ways to choose the best Vibrating Screen ...

Zenith Vibrating Feeder is built to withstand the toughest work in a quarry or mine by matching different appliions; The feeder series is designed particularly for continuous use with any hard and abrasive materials through uniform flow. They a...

Vibratory Screens | McLanahan

Screening is an important part of processing and is used to separate material according to its size. Material is typically fed to a single, double or tripledeck screen to make the required sizes. Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specifiion. Material must go through or over a specified size to end up in the ...

Manufacturers of Circular Motion Vibrating Screens for ...

A Type Circular Motion Vibrating Screen is consisted of Screen box, Screen, Vibrating motor, Reducing setting and Base plate. The angle of the screen could be changed by the adjustment of the height of the base plate. Usually the vibrating motor is fixed on the right side of the screen frame. We have all sorts of screens for our users to choose.

Steel Shot vibrating screen

Required equipment:Vibrating Sieve,Linear vibrating sieve. Screening aim. For size grading, rust removal for the workpiece, the particle size uniformity is high, so blasting steel shot manufacturers need to use the vibrating screen for particle size grading and larger particles removal, so as to ensure the uniformity of steel particle size.

What factors affect the screening accuracy of the square ...

Jul 22, 2020 · If you want to achieve a screening accuracy of more than 98%, you need to choose a standard [No. sieve]. The mesh size is (screen number 5#600#). 2. Exciting force. The power source of the square rocking screen is the vibration motors on both sides of the equipment.

meshes for vibrating screens

Vibrating Screen Mesh for Mineral And Metallurgy. Vibrating Screen Mesh Wear and Abrasion Resistance. Vibrating screen mesh is mainly used on vibrating screen machines for screening and sizing all kinds of sand, gravel, coal, stone, rock and other materials in mineral, metallurgy, quarry and .

Copyright © .CMichineAll rights reserved.خريطة الموقع