- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Coke (fuel)

Coke is a grey, hard, and porous fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.. The unqualified term "coke" usually refers to the product derived from low ...

AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING ...

Coke is the carbon product that is formed by the thermal distillation of coal at high temperatures in the absence of air in coke oven batteries. Coke is used in the blast furnace to provide a reducing atmosphere and is also a source of fuel. Most coke in the United States () is produced in byproduct recovery coke oven batteries, which recover tar, light oil, ammonia, and coke oven gas ...

Coking Process

It has been shown that multistage coking [1–4] meets both objectives with coking coals blended for current use in the coking industry. In this study, a multistage coking process is applied to noncoking coals, to find how the properties of coals are modified to influence the tar yield and strength of formed cokes produced in the process. Solvent impregnation has been reported to enhance ...

Direct Reduction Process

Use of coal and coke breeze for sintering is out of the scope of this contribution. Furthermore, alternatives to coal materials and energy sources such as biomass or waste plastics are discussed, which are of great importance in the course of efforts to recycle secondary sources and to mitigate carbon dioxide emissions due to the global climate change challenge. Steel production routes ...

Coke and Chemistry | Home

· Coke and Chemistry is a peer reviewed journal. We use a single blind peer review format. Our team of reviewers includes 15 experts. The average period from submission to first decision in 2019 was 14 days, and that from first decision to acceptance was 30 days. The rejection rate for submitted manuscripts in 2019 was 15%.

Blacksmithing coke for sale | Farmweld

· Farmweld's high quality coke produces low ash and is great for blacksmithing, AGA stoves, coke fired steam boilers, etc. Compared to charcoal and other combustible materials, coke is relatively smoke free as most of the volatiles are burnt out of it. This is important in any setting where air quality is imperative. It is an excellent source of heat for the forge due to the amount of heat it ...

Coke oven emissions means the benzenesoluble fraction of total particulate matter present during the destructive distillation or carbonization of coal for the production of coke. Director means the Director, National Institute for Occupational Safety and Health, Department of Health, Eduion, and Welfare, or his or her designee.

Coking coal of the United States—Modern and historical ...

Coking coal, or metallurgical coal, has been produced in the United States for nearly 200 years. Coking coal is primarily used in the production of coke for use in the steel industry, and for other uses (for example, foundries, blacksmithing, heating buildings, and brewing). Currently, coking coal is produced in Alabama, Arkansas, Pennsylvania, ia, and West ia.

Coke Production

Metallurgical coke is produced by the destructive distillation of coal in coke ovens. Prepared coal is heated in an oxygenfree atmosphere (–coked–) until most volatile components in the coal are removed. The material remaining is a carbon mass called coke. Metallurgical coke is used in iron and steel industry processes (primarily in blast furnaces) to reduce iron ore to iron. Over 90 ...

51 Uses for CocaCola – the Ultimate List

· Coke does not contain cocaine (although it used to). Coke did not become carbonated by accident. So, that's what my days of research turned up (yes, days. Anyone who tells me to get a .

Coke Making Process

Coal is the largest source of energy for the generation of electricity worldwide and is also used in the production of metallurgical coke as blast furnace fuel. Some smaller blast furnaces can utilize charcoal as a carbon source, but the larger blast furnaces require the strength and durability of coke. Coke is produced by igniting bituminous coal under reduced oxygen conditions in oven ...

Coke Oven

· The principal type of coke oven in general use is the slot oven. This equipment, which can be used either with or without a byproduct recovery process, consists of a narrow refactory chamber closed by removable doors at each end. A charge of coal is introduced through a hole in the top, leveled, and then heated, after the oven is sealed, by combustion of coal gas in heating flues at the sides ...

Coke Oven | Feed The Beast Wiki | Fandom

The Coke Oven is a 3x3x3 structure built similarly to the Blast is used to produce Coal Coke (used as an alternative to Charcoal in the Blast Furnace) and Creosote structure is made by placing Coke Oven Bricks in a 3x3x3 cube without the middle block. 104 Brick and 130 Sand are required to create one Coke Oven, a total of 26 Coke Oven Bricks.

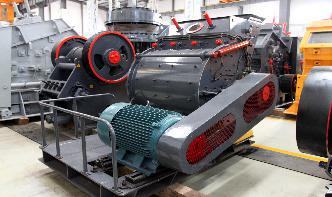

equipment used for coke and coal

Type of crusher used in coke oven plant for crusher coal mobile equipment used coal plants Get Price. executive . China coal coke machinery wholesale 🇨🇳 Alibaba. A wide variety of coal coke machinery options are available to you, such as beverage, machinery hardware, and apparel. You can also choose from free samples, paid samples. There are 7,063 coal coke machinery suppliers ...

Safety Guidelines for Coke Ovens Coal Chemicals

The main function of Coke Ovens is to convert coal into coke which is used as a fuel and reducing agent in the Blast Furnace. Its secondary function is to recover Volatile Matter and CO (Coke Oven) gas from coal and extract chemicals known as Coal Chemicals. CO gas produced is used for heating purposes in the plant. Heat from hot coke is extracted steam is generated at Coke Dry Cooling Plant ...

Coke Manufacturing

•Use enclosed conveyors and sieves for coal and coke handling. Use sprinklers and plastic emulsions to suppress dust formation. Provide windbreaks where feasible. Store materials in bunkers or warehouses. Reduce drop distances. • Use and preheat highgrade coal to reduce coking time, increase throughput, reduce fuel consumption, and minimize thermal shock to refractory bricks. Coke Oven ...

Coal Coke Test Equipment

Coal Coke Test Equipment. The range of coal and coke tests carried out in a furnace or oven has grown over many years, and Carbolite Gero has responded to the requirements of each new standard by designing a furnace to suit the specific requirements of each test method. As a result, Carbolite Gero products are frequently specified as the ...

Copyright © .CMichineAll rights reserved.خريطة الموقع