- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Mekanism Ore Processing

Mekanism provides 4 tiers of systems to process ores and obtain two to five ingots from 1 ore. The complexity of the systems rises with each tier and at the higher tiers various secondary machines are required to produce consumables for the main ore processing line. The following page shows the layout of these systems as well as some ingame pictures and descriptions. All machines are only ...

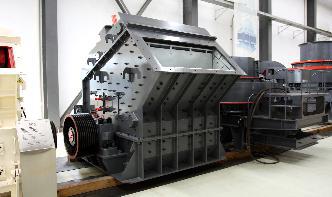

Crushing Process For Copper Ore Crusher Machine Supplier Ton

Crushing Process For Copper Ore Crusher Machine Supplier Ton Mobile jaw crusher simmons cone crushe. European type jaw crusher is a new crushing machine, the jaw crusher manufacturer, after the release of traditional jaw crusher. this jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of ...

crushing circuit for iron ore process

iron ore crushing schematic circuits. Crushing Circuit For Iron Ore Process ALIKODeutschland. Crushing Circuit For Iron Ore Process Crushing is the process of transferring a force amplified by mechanical most initial ore crush beneficiation of iron ore mineral processing extractive metallurgy crushing is done in the conventional manner in 2 or 3 all in closed circuit .

5 Gold Extraction Methods to Improve Your Recovery Rate ...

12/07/2021 · 4 Stages to process gold ores Ⅰ. Crushing and screening stage The crushing and screening stage in the industry is mainly composed of threestage and a closedcircuit process. Gold ores need to go through coarse, medium, and fine crushing processes to be minimized into smaller pieces. The screening equipment is used to sieving the smaller gold ...

Metallurgy

1. Crushing and grinding: The first process in metallurgy is crushing of ores into a fine powder in a crusher or ball mill. This process is known as pulverization. 2. The concentration of ores: The process of removing impurities from ore is known as a concentration of minerals or ore dressing. In metallurgy, we concentrate the ores mainly by ...

ASARCO » Milling

The primary crusher may send the crushed ore on to a secondary crusher or pile it directly onto the coarse ore stockpile. TOUR NOTE: On your tour from the Mineral Discovery Center, you may get to see the haul trucks dumping ore into the crusher. Grinding The ore is ground into a fine powder by large rotating mills. The two types used in the ...

How gold is extracted by Cyanidation Process

17/06/2020 · The process of extracting gold by cyanidation process involves three important steps that have to be looked into: The first step involves bringing the finely ground ore and the cyanide solution, Then removing the solids from the clear solution, and. Lastly recovering precious metals from the clear solution by a method known as the precipitation ...

crushing of ore process

Ore crushing and milling process analysis zenith Heavy . Mining ore crushing and milling to the selected granularity ore particle size is reduced to a few thouhs of the original or even one ten thouh of the . Service Online; Crushing definition of crushing by The Free Dictionary.

process of crushing ores

process of crushing ores. What process is crushing the ore YouTube. Gold Ore Crushing Process. Gold ore is one of the world s leading precious metal ores. It not only plays an important role in the industry and in life but also the reserveof it is an important basis for maintaining financial stability.

PGM Ore Processing at Impala's UG2 Concentrator

the two ore components is best exploited by fully autogenous grinding, rather than semiautogenous grinding. This also allows for crushing of the sizeable stream of silie pebbles discharging from the autogenous mills, without risk of crusher damage through missdirected grinding media. This way, it was believed that the primary mill

crushing of ore process

process of crushing and heating ore. Process Of Crushing And Heating Ore Setting Up A Rock Crushing Plant MINIG machine. Rock crushing plant pdf ock crushing mar 16 2017 crusher wikipedia crusher is a machine reduce large rocks into smaller rocks gravel or may be used to reduce the size or change the form ...

process of platinum ore crushing

process of crushing ores. The milling process begins with crushing run of mine (ROM) ore to minus five inches in a 42 inch x 48 inch jaw crusher. The crushed ore is then conveyed to a gasfired drier where the crushed material is dried to about 1 moisture.

Ore Crushing Principles And Process

ore crushing principles and process ore crushing plant principle Ore Crushing Plant Principle; The production of pig iron from crushing plant waste using Crushing plant waste in the form of iron ore powder can be used as raw material for iron preparing process With a low iron content is 56%, the process to increasing of Fe.

CHAPTER 1 MINERAL DRESSING

any ore dressing plant is to aim at liberation by size reduction or comminution. Comminution of any ore is carried out in several stages using different crushing equipments. So the objective crushing is to reduce the large lumps in to smaller sizes. Depending upon the feed and product particle size, the crushing

Finely ground ore crushing process

Jan 04, 2015 · Finely crushing process is among the most critical processes, but also the highest consumption of energy a program. Therefore, strengthening the broken features, stone quarries and other mining and ore mined is about crushing to a particle size is reduced to a minimum and is technically feasible to meet the size of the next work program ...

Taconite Ore Processing

fine grinding. Prior to grinding, the ore is drycrushed in up to six stages, depending on the hardness of the ore. One or two stages of crushing may be performed at the mine prior to shipping the raw material to the processing facility. Gyratory crushers are generally used for primary crushing, and cone crushers are used for secondary and ...

iron processing

Crushing and screening are straightforward mechanical operations that do not alter an ore's composition, but some ores need to be upgraded before smelting. Concentration refers to the methods of producing ore fractions richer in iron and lower in silica than the original material.

Crushing | McLanahan

Crushing. Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant. The type of crusher required depends on the material being reduced. McLanahan specializes in a variety of crushing solutions for reducing minerals ...

process of crushing ores

process of crushing the copper ore. Copper Ores and Copper Mining Process Copper crushing process machines. Crushing Primary . Primary crushing was done by a jaw crusher like a giant nutcracker. This consisted of two jaws, one static, and one moving. Ore would move between the jaws and ...

Mineral processing | metallurgy | Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive primary operations are comminution and concentration, but there are other important operations ...

Crushing Plant

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. mm and the t/m 3. The work index of the ore was determined as kWh/t. A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 μm. A 30% pulp was made and charged to the mill, which was then ...

four stages in crushing circuit | Stone Crusher used for ...

21/01/2012 · all these stages consist a whole process of crushing circuit. Of course, not all crushing circuits are including four stages, some stages are optional according to the working site condition, ore characteristics etc. jaw crusher is wellknown for primary crushing, impact crusher is for secondary crushing, cone crusher and impact crusher maybe ...

Crushing Of Ore Process

Crushing process the three sections of closedcircuit crushing is one of the most modern suitable for high hardness of the iron ore crushing can finish the ore crushing and part of the solution from the job thereby improving the efficiency of subsequent grinding grinding process the second section is a closed grinding efficient grinding.

crushing of ore process

crushing process of gold ore . crushing process of gold ore Machine For, crushing process of gold ore manufacturer in Shanghai, China crushing process of gold ore is manufactured from Shanghai ZME,It is the main mineral processing . >>Get Price ; Processes for Beneficiation of Iron Ores Crushing and grinding. Inquire Now

Copyright © .CMichineAll rights reserved.خريطة الموقع