- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Preparation for IELTS Exam

Diagram. Sometimes IELTS Writing Task 1 requires you to describe a process. If you have a 'describing a process' task in the exam, you will be given a diagram with a series of pictures. The diagram shows the stages of how something is made or how something works.

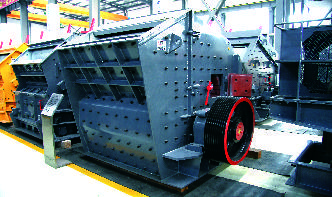

Cement mill

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

SmartDraw Templates and Examples

SmartDraw Templates and Examples. Edit this example. AWS Diagram. Edit this example. Cause and Effect. Edit this example. Charts and Gauges. Edit this example. Decision Trees.

iHandbook | Schlumberger

iHandbook, an electronic version of the Field Data Handbook, displays data that helps compute results fast. This eliminates the timeconsuming and errorprone practice of first assimilating data and obtaining results using a separate calculator. The iHandbook was designed with three objectives: retain the book format of the Field Data Handbook.

JK Cement :: India's Premier Cement Company

At JK White Cement Works, Gotan we use technical expertise from Co. from Denmark and state of the art technology with continuous online quality control by micro processors and Xrays to ensure that only the purest White Cement is produced. We manufacture White Portland Cement through these 5 significant stages Crushing, raw ...

Cement Production Line

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

IELTS Diagram: Model Answer Band Score 9

Mar 03, 2018 · The diagram provides information about the different levels and tools required in the production of cement, and how cement contributes to the making of concrete for construction purposes. Overall, the manufacturing of cement requires a dry process, while concrete production on .

Cementing Services | Schlumberger

Achieve longterm zonal isolation in any environment. Cement supports and protects well casings and helps achieve zonal isolation. Critical to safer, environmentally sound, and profitable wells, zonal isolation is created and maintained in the wellbore by the cementing process. Whatever your drilling environment or however remote the loion ...

A customised bottling line for each container type

A customised bottling line for each container type. Whether for glass bottles, PET containers or cans, for filling, labelling or packing, for water, beer or soft drinks – Krones offers a customised system solution for every process step, every container type and every beverage egory. The wide portfolio comprises all machines required for ...

General Principles of Well Barriers | SpringerLink

Jan 28, 2020 · A well barrier diagram is a network illustrating all possible leak paths from the reservoir to the surroundings. The surroundings could be the sea for subsea wells, platform deck for a topside Christmas tree, flowline from a subsea well, ground for onshore wells, etc. Figure shows the well barrier diagram for the production well in Fig. ...

Emissions by sector

Cement (3%): carbon dioxide is produced as a byproduct of a chemical conversion process used in the production of clinker, a component of cement. In this reaction, limestone (CaCO 3 ) is converted to lime (CaO), and produces CO 2 as a byproduct.

Concrete Design Production

Concrete Design Production. Concrete is a mixture of two components: aggregates and paste. The paste, comprised of cement and water, binds the aggregates (usually sand and gravel or crushed stone) into a rocklike mass as the paste hardens. A properly proportioned concrete mix possesses acceptable workability of the freshly mixed concrete and ...

HolcimLogistic Content CS5 FA 1358 | PDF | Logistics ...

REFERENSI: REFERENCES: • HLM 2425: Diagram Proses Bisnis • PAGE 2425: Business Process Diagram • HLM 30: Skema Distribusi Semen • Jawa • PAGE 30: Cement Distribution Scheme • Java 44 PETA PER AN TANGGUNG JAWAB • HLM 36: Diagram Peran Tanggung Jawab • PAGE 36: Role Responsibility Diagram ROLES RESPONSIB IL I T Y M AP 45 ...

Concrete Product Machines and Solutions

EXPLORE OUR SOLUTIONS. Columbia Machine is one of the world's leading manufacturers of concrete products equipment, serving customers for over 80 years, in over 100 countries. From mixing and batching to automatic cubing and splitting, Columbia builds a complete line of equipment to outfit your entire concrete products plant.

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Copyright © .CMichineAll rights reserved.خريطة الموقع