- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Sand Casting Process, Prices, Equipments, Materials ...

Casting Process. We need make wooden, resin or metal patterns according to the drawings or samples. Then, we put patterns into the sand boxes, then put green sand or resin sand into the boxes, then make the sand become solid by pressure come from molding machines or manual methods, then take the patterns out, and so, the space taken by patterns will become hollow, then inject melted liquid ...

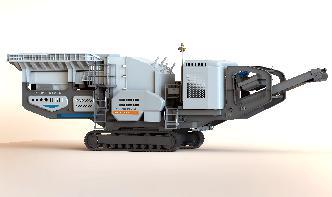

Construction Equipment Types And Construction Equipment List

· Image: Loader. A loader is a heavy equipment machine used in construction to move aside or load materials such as asphalt, demolition debris, dirt, snow, feed, gravel, logs, raw minerals, recycled material, rock, sand, woodchips, etc. into or onto another type of machinery (such as a dump truck, conveyor belt, feedhopper, or railroad car).

Types of sand casting tools and equipment

· Types of foundry or casting tools and equipment used in foundry shops are used for carrying out different operations. such as sand preparation, pouring, molding, and casting. These tools are classified as hand tools and conditioning tools. They are; flasks, poweroperated equipment, metal melting equipment, and fettling and finishing equipment.

Sand And Gravel Processing

11/95 Sand And Gravel Processing Sand And Gravel Processing ... by dredging involves mounting the equipment on boats or barges and removing the sand and gravel from the bottom of the body of water by suction or buckettype dredges. After mining, the materials are transported to the processing plant by suction pump, earth mover, barge, truck, belt conveyors, or other means ...

Shell molding

Shell molding, also known as shellmold casting, is an expendable mold casting process that uses resin covered sand to form the compared to sand casting, this process has better dimensional accuracy, a higher productivity rate, and lower labour is used for small to medium parts that require high precision. Shell moulding was developed as a manufacturing process during ...

From sandy beach to Kaby Lake: How sand becomes silicon ...

· From sandy beach to Kaby Lake: How sand becomes silicon. By PC Plus, Carrie Marshall (PC Plus Issue 281) 25 August 2016. The amazing journey that ends up with a processor .

How to Make Gravel and Sand

· How to make gravel and sand The Gravel and Sand Making Flowsheet. Depending on the type of equipment used for excavating the gravel, the method of transporting material from the pit to the plant is between conveyors, trucks, or where size permits, pumps and pipe lines. In a conveyor system the use of a movable feed hopper equipped with a ...

Materials Wet Processing Equipment

CDE Global is the world's number one wet processing equipment company for sand and aggregates, mining, CD waste recycling and industrial sands. Customer Login. Region : Language: Search. Careers; About Us; News; Events; Brochures +44 28 8676 7900 Contact. Products. Wet Classifiion. EvoWash; Combo; FreeFlow Mobile Wash Plant; DLine Dewatering Screens; FLine Fine Screens; M .

Foundry Machines, Foundry Sand Testing Equipments ...

Foundry Machines, Foundry Sand Testing Equipments, Metal Testing Equipments, Sand Plants, Intensive Mixers, In Line Knockout Machines, Manufacturer, Kolhapur ...

The Nobake Process :: Vulcan Engineering Co.

The sand can now be either reclaimed for reuse in the casting process or removed for disposal. Thermal reclamation is the most efficient, complete method of Nobake sand reclamation. Vulcan Engineering Co. provides a large line of Nobake equipment, including mold pouring, mold handling and sand conditioning. More Info >>

Sand Casting Process, Defects, Design

Moldmaking The first step in the sand casting process is to create the mold for the casting. In an expendable mold process, this step must be performed for each casting. A sand mold is formed by packing sand into each half of the mold. The sand is packed around the pattern, which is a replica of the external shape of the casting. When the pattern is removed, the cavity that will form the ...

Mold Core Making Sand, Equipment Supplies | Midvale ...

Create quality metal castings with our mold core making equipment and supplies. Providing sands, riser aids, mold sealer, mold making equipment, coatings, additives, binders more. Avoid any OSHA PEL concerns by converting to one of our many silica free mold and core sands. Green Diamond Molding Sand. Molding sand that comes in Ferrous and NonFerrous options in multiple screens. *SILICA ...

Sandbag Filling Equipment for Construction Flood Control

Logistics become much simpler as crating and transporting costs are all but eliminated along with the required equipment to do those tasks. As exhausting and destructive to the human body as current sand bagging operations are, it only makes sense to use horsepower for sandbag filling as opposed to manpower. Further, horsepower produces more reliable and predictable results safely. All other ...

Artificial Sand Making Machines, Jaw Crushers, Cone ...

· Akashganga invented a novel process for separating dust . It is a dry Process requires no water. This process is much economical and more efficient. In Water Washing fine particles of sand are swept away, makes the sand inferior quality. The dust separating Machine invented by Akashganga is also very useful in Mineral Industries. Iron Ore ...

Palmer Universal Molding Machine

Tooling is often new, old, cope/drag, matchplate, green sand, nobake, shell, metal, wood, plastic, or any combination thereof. Quantities can range from 1 or 2 pieces up to hundreds or thousands. The Palmer UMM and FMM were designed to be a high production NoBake molding system with low capital costs that could make Nobake molds with any of this tooling with minimal setup, minimal tooling ...

Sand casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called 60% of all metal castings are produced via sand casting process.

Sand Making Machine,Zenith Sand Making Machine Supplier

Powerful Sand Making Machine. Zenith VSI Sand Making Machine,also called B series VSI crusher, is one of the most advanced impact crushers nowadays. Sand making machine is our sole patent using central feeding central cascade feeding, which can be changed based on customers'needs.

A MODEL FOR FOUNDRY MOLDING EQUIPMENT

Production and Process Alternatives 22 Pattern and Core Box Making 22 Moldmaking 24 Coremaking 27 Sand Handling: Reclamation, Preparation, 27 and Distribution Melting Section 33 Cleanout, Casting Cleaning, and Inspection 36 Technological Progress in Green Sand Molding 37 Moldmaking 38 Melting Operations 39 Quality Control 39

How sand is made

Quartz sands, which are high in silica content, are used to make glass. When quartz sands are crushed they produce particles with sharp, angular edges that are sometimes used to make sandpaper for smoothing wood. Some quartz sand is found in the form of sandstone. Sandstone is a sedimentary, rocklike material formed under pressure and composed of sand particles held together by a cementing ...

Tile Adhesive Manufacturing Plant for Sale from Aimix Group

That makes tile bond making machine a business worth investing in. ... Main Components Of The Tile Adhesive Making Machine: Wet Sand Drying System: equipped with Triplecylinder dryer to reduce the sand water content to ≤%; Raw Materials Storage System: cement silos are used to store the raw materials ; Hoisting System: bucket elevator; Conveying System: belt conveyor, screw conveyor ...

Silicon Wafer Processing

Most of the sand used for these processes is shipped from the beaches of Australia. Step 2: Preparing the Molten Silicon Bath The sand (SiO2)is taken and put into a crucible and is heated to about 1600 degrees C – just above its melting point. The molten sand will become the source of the silicon that will be the wafer. Step 3: Making the Ingot A pure silicon seed crystal is now placed into ...

Copyright © .CMichineAll rights reserved.خريطة الموقع