- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

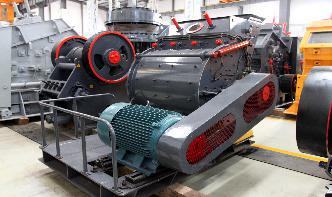

Ball Mill

Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel.

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill ...

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills,you can .

How iron is made

then reacts with the iron ore to form carbon dioxide and pure iron. Separating the iron from the slag 2 The melted iron sinks to the bottom of the furnace. The limestone combines with the rock and other impurities in the ore to form a slag which is lighter than the iron and floats on top.

Iron Extraction by Blast Furnace Metallurgy

Crushing and grinding: The crushing of ores into a fine powder in a crusher or ball mill is the first step of Metallurgy. 2. The concentration of ores: The next process of Metallurgy to separate impurities from ore is known as a concentration of minerals or ore dressing.

Minerals Processing

Minerals Processing Our TAKRAF brand provides a host of comminution equipment ranging from sizers to doubleroll crushers and HighPressure Grinding Rolls (HPGRs), whilst our global DELKOR brand focusses on liquid/solid separation and beneficiation with thousands of successful installations worldwide. DELKOR products are specifically designed for the rigors of the mining industry, combining ...

Our Operation

Jun 30, 2021 · First the ore goes into autogenous grinding mills and then ball mills, where the crushing process continues until it's a fine powder. At intervals in the crushing process, magnetic separation draws the valuable magnetite concentrate away from waste.

Solomon Hub Iron Ore Mine

The ore processing facility (OPF) at Firetail will process bedded iron ore for the first two years of mining. The deposits will be dryprocessed for the direct shipping of ore. The ore is crushed in the primary crushing hub and transported back to the OPFs for grinding and separation.

FL | Driving sustainable productivity

FL provides sustainable productivity to the global mining and cement industries. We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental impact.

XRay Fluorescence (XRF)

Jan 21, 2020 · The XRF method depends on fundamental principles that are common to several other instrumental methods involving interactions between electron beams and xrays with samples, including: Xray spectroscopy (, SEM EDS), Xray diffraction (), and wavelength dispersive spectroscopy (microprobe WDS). The analysis of major and trace elements in geological materials by xray fluorescence .

Special Wastes | Hazardous Waste | US EPA

Apr 08, 2021 · History. Mining waste is one type of special waste When EPA proposed regulations for managing hazardous waste under Subtitle C of Resource Conservation and Recovery Act (RCRA) on December 18, 1978 (43 FR 58946), the agency deferred hazardous waste requirements for six egories of waste—which EPA termed "special wastes"—until further study and assessment could be completed .

Ball Mills

mills with an external separation system, in which a prepared product is separated from the under milled powder in separators outside of the mill drum. ... Developments in iron ore comminution and classifiion technologies. A. Jankovic, in Iron Ore, 2015. ... so the comminution process in the first chamber is dominated by crushing. In the ...

Bryah ups Gabanintha nickel, copper and cobalt resource by ...

Jun 01, 2021 · Bryah has upgraded resources at its Gabanintha project in Western Australia that includes an indied component within planned open pits. The resource at Gabanintha now stands at million tonnes grading 761 parts per million (ppm) nickel, 210ppm copper and 228ppm cobalt, or a contained resource of 23,770t of nickel, 6,556t of copper and 7,116t of cobalt.

Mineral processing | metallurgy | Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Copyright © .CMichineAll rights reserved.خريطة الموقع