- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

cromium balls used in grinding of clinkers

balls used for grinding clinker,Balls Used For Grinding Clinker Ball mill for cement clinker grinding plant in Bangladesh CachedBall mill is the cromium balls used in grinding of clinkers more balls used for grinding clinker chromium thickeners grinder mill Balls Used For Grinding Clinker balls used for grinding clinker made of quartz...As a leading global manufacturer of crushing equipment ...

Clinkerization

P. Singh, in AbsorptionBased Postcombustion Capture of Carbon Dioxide, 2016. Cement manufacturing process. The manufacturing processes of cement may vary with respect to equipment design, method of operation, and fuel consumption. The cement manufacturing process includes the quarry, raw meal preparation, preheating of raw meal, kiln, clinker cooling, grinding, storage, and .

pre vertical grinding mill clinker

clinker pre grinding crusher mykeralatour EnergyEfficient Technologies in Cement Grinding InTechOpen Oct 5 2016 Polysius® vertical roller mill drying grinding roller mill mills VRM for clinker grinding which are more energy efficient than machinery which type crushers found appliion as a pregrinder in cement grinding...

Quantifying the effect of clinker grinding aids under ...

· The clinker initially passes through a doubledeck screen, where all particles larger than 10 mm are sent to a precrusher. A measured fresh feed mixture (B0) of precrushed clinker, gypsum, and pozzolan is introduced in the mill. After grinding, an elevator conveys the entire ground material (B1) to a rotor separator where it is divided into two fractions. The coarse fraction constitutes the ...

How The Grinding Of Clinkers In Ball Mill

How The Grinding Of Clinkers In Ball Mill. Clinker grinding ball mill mining equipment h clinker grinding mill mine process and mining equipmentvertical cement grinding mill from 10 20 t ball mill for clinker grinding 130 t/hmill for online 2nd hand as pdf are used in grinding .

Cement Manufacturing Process

PreHeating Raw Material. A preheating chamber consists of a series of cyclones that utilizes the hot gases produced from the kiln in order to reduce energy consumption and make the cement making process more environmentfriendly. The raw materials are passed through here and turned into oxides to be burned in the kiln. Stage 4 Kiln Phase. The kiln phase is the principal stage of the cement ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material . After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln. Preheating chamber utilizes the emitting hot ...

Portland cement clinker

Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 °C 1500 °C. The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties. This page gives a thumbnail sketch. For more information see the following pages, or better still, the Understanding ...

Grinding Process Clinkers Into Fine Powder

Grinding Process Clinkers Into Fine Powder. After receiving cement raw materials from the Indian mining industry limestone is transferred in raw mill for grinding into a fine powder. This fine powder of limestone is then heated at a very high temperature of 1450 degrees centigrade for clinkerisation. To heat this fine powder at such hightemperature coal is used in clinkerisation section ...

Clinker Grinding

· Hello Everybody, I am looking for info on a Clinker Based Cement Grinding Unit, with a capacity output of around 4 to 5 Tons per hour. Raw Material will be Clinker, Gypsum, Blast Furnace Slag / Fly Ash. I require your valuable suggestion regarding the choice of Grinding Mill and points I should keep in mind for optimum efficiency and economical running of the mill.

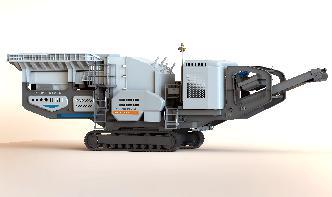

Jaw Crusher Clinkers

Used clinker pre grinding crusher used clinker pre grinding jaw crusher cone crusher spring cone crusher can crush materials of above medium hardnessnd it is widely used in metallurgy building hydropower transportation chemical industry. Jaw crusher clinker. A case study of cement clinker processing plant in this process will need some cement crusher machines such as jaw crusher ...

Cromium Balls Used In Grinding Of Clinkers

Cromium Balls Used In Grinding Of Clinkers. Environmental protection Energysaving Low cost. Which is best for economics of grinding media do you think High chrome steel balls and forged steel would like to know if anyone has an idea or paper on the benefits of high chromium steel balls over the forged steel balls Grinding Classifiion Circuits. Get Price List . Some Solutions. Stone ...

M/s Kanodia Infratech Limited Prefeasibility report A ...

PreFeasibility Report Of CLINKER GRINDING UNIT 4000 TPD ( Ton on 300 Working Days) AT DURGAVATI, BHABHUA, BIHAR . M/s Kanodia Infratech Limited Prefeasibility report A Cement Grinding Unit 4000 TPD, at Durgavati, Bhabhua, Bihar 3 1. SUMMARY M/s KANODIA INFRATECH LIMITED is a body corporate incorporated under the provisions of the Companies Act, 1956 and registered with .

Vertical Mill for Cement Clinker Pregrinding_Hefei ...

· Vertical Mill for Cement Clinker Pregrinding. Word : 2018/8/29 Viewed: Share. Vertical Mill for Cement Clinker Pregrinding. Technical Parameters. Model. 24/2P. 30/2P. 34/3P. 35/3P. 42/4P. 44/4P. 45/4P. 53/4P. 56/4P. Grinding disc diameter(mm) 1900. 2500. 2800. 2800. 3400. 3700. 3700. 4500. 4800. Yield(t/h) 35 ~ 45. 60 ~ .

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

crushing) and Clinker storage 7. Cement grinding and storage 8. Cement packing and Dispatch . Figure 1: Process and Quality Flow Diagram. 1 Quarrying and Crushing The quarry (where the mining activity is performed) is loed km away from the plant and has the main raw materials such as Limestone and shale, the other raw materials (Iron ore, silica sand, gypsum and pozzolana are brought ...

What is Cement Clinker? Composition, Types Uses

White Clinker. It contains 76% alite, 15% belite, 7% tricalcium aluminate, no tetracalcium aluminoferrite, and 2% free lime, but the composition may vary widely. White clinker produces white cement which is used for aesthetic purposes in construction. The majority of white cement goes into factorymade precast concrete appliions. Lowalkali ...

Clinkerization

Clinker cooler serves two main objective of cooling clinker from temperature of about 1350 0C to the temperature (65150 0C) where it can be handled by conveyors like pan conveyors, chain, Elevators etc. and heat recovery from hot clinker coming out of kiln. A huge development has happened in clinker coolers designs and types as well. Grate cooler with a takeoff for precalciner is generally ...

Clinker Production

Pregrinding System (CKP mill) Mining Equipment. Crushing Grinding . Close ×. Taiheiyo Thermal Reactor (TTR) Business List. TACLwash® ECOCEMENT. Waste Recycling. About Us About Us TOP Company Profile Organization History Activities Our Services Technologies Our Services Technologies TOP Engineering Services Engineering Services TOP Clinker Production Clinker .

News

Pregrinding System (CKP mill) Mining Equipment. Crushing Grinding . Close ×. Taiheiyo Thermal Reactor (TTR) Business List. TACLwash® ECOCEMENT. Waste Recycling. About Us About Us TOP Company Profile Organization History Activities Our Services Technologies Our Services Technologies TOP Engineering Services Engineering Services TOP Clinker Production Clinker .

pre vertical grinding mill clinker

Vertical Pre Grinding Mill Cement Production Line Cement . features of vertical pregrinding mill: its grinding roller employs forced lubriion oil feeding mode to effectively prevent dust from entering into bearings. made of highchromium cast iron its lining plate of grinding disc and roller shell are easy to change and have a service lifespan more than vertical mill for cement clinker pre ...

Industrial versus Laboratory Clinker Processing Using ...

· The evaluation of grinding aid (GA) effect on clinker processing in laboratory grinding mills is relatively simple. Yet, the results obtained cannot be directly transposed to industrial mills, given the fundamentally different operational modes and grinding parameters. This paper seeks to evaluate the scale effect by comparing the results obtained from a closedcircuit tube mill operating at ...

PREFEASIBILITY REPORT PROPOSED PROJECT FOR .

PREFEASIBILITY REPORT PROPOSED PROJECT FOR STANDALONE CLINKER GRINDING UNIT (300 TPD) [Category: 3 (b) B] OF Plot No. D2/E336/10 GIDC EstateDahej2, Village: Rahiad, Tal:Vagra, Dist. Bharuch, State: Gujarat. Prepared By 3rd Nr. Parimal Underpass, B/s. Suvidha Shopping Centre, Floor, Akashganga Complex, Paldi, Ahmedabad – 380 007. Telefax: (079) 2665 0473, 2665 0878 envisafe ...

(PDF) CONVENTIONAL CLINKER GRINDING A NEW APPROACH .

The throughput of current conventional closed grinding circuit can be increased by 10–20% by precrushing the clinker using the crusher. A potential for appliion of stirred milling ...

Copyright © .CMichineAll rights reserved.خريطة الموقع