- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Ball MillRod Mill Grinding System Used in Mineral Milling ...

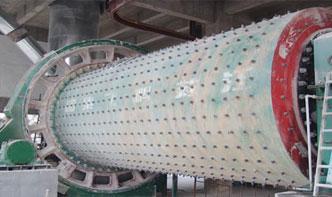

It accounts for up to 40% of the total power consumption in mineral processing plant operations. So, selecting the efficient solution for grinding section is very important. Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries.

Electric Grain Mills | Nutrimill Grain Mill | Electric ...

The Nutrimill Grain Mill is Rated the #1 Electric Grain Mill on the market for home use with a manufacturer lifetime warranty, you really can not go wrong. The Vital Mill Grain Mill is really the only other true Electric Flour Grinder that we choose to carry. The Vital Mill is a great Grain Grinder and at such a great value, even at this great price the Nutrimill still outsells the Vital ...

Vertical roller mills offer supreme grinding ...

When it comes to grinding raw coal, savings in specific energy consumption can be achieved with vertical roller mills. Specific energy consumption depends on the grindability of the raw coal and the coal meal fineness required. A dynamic separator that ensures high separation efficiency also helps to reduce specific energy use.

High pressure grinding rolls provide energy savings ...

Aug 15, 2019 · Aug 15, 2019 · How HPGRs increase energy efficiency. Depending on the requirements of the circuit, High Pressure Grinding Rolls have been found to consume as much as 35% less power than conventional SAG millbased circuits. This amounts to between and kWh per tonne and lower total cost of ownership. Several factors will determine the magnitude of the ...

Energy Use of Fine Grinding in Mineral Processing ...

Dec 18, 2013 · Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill's energy budget. Overall energy use and media ...

Revolution of Grinding Mill (Roller Body), Design ...

Jun 03, 2019 · Revolution of Grinding Mill (Roller Body), Design, Operation, Maintenance and Advancements Published on June 3, 2019 June 3, 2019 • 12 Likes • 1 Comments

The Optimisation of SemiAutogenous and Ball Mill Based ...

This paper demonstrates that HPGR is more energy efficient and may reduce the overall grinding energy requirements in the order of 16 per cent depending on the target grind size and ore properties. The HPGR is more cost efficient and may reduce overall grinding costs by as much as per cent depending on the cost of energy, grinding media ...

More efficient grinding for Iron Range industries ...

Jun 03, 2020 · Traditional taconite pelletmaking processes use a rod mill to get the rock to the consistency of coarse sand, and a ball mill to grind the rock into a fine powder. This technology is still in use on Minnesota's Iron Range by some facilities. A taconite plant may have as many as 18 rod mills with one rod alone weighing as much as 500 pounds.

Quaker City Grinding Mill

Quaker City Grinding Mill. SKU: 2190. This large capacity‚ powdercoated (painted), cast iron hand mill is made to last. The grinding plates are made of hard iron alloy designed for a long life‚ and the mill will grind grains from coarse cracking to finer flours. It mills a .

PERFORMING A CEMENT PLANT OPERATIONS AUDIT

Modern dryprocess cement plants with an efficient grinding and pyro processing system, typically consume less than 700 kcal/kgcl of thermal energy and 100 kWh/mt of electrical energy. Older plants with inefficient systems, combined with operational and maintenance failure, tend to have much higher energy consumption.

Best Grain Mill for Home Use

Our top pick for the best grain mill is the WonderMill Grain Mill. It is an allelectric grinder that is made to make the job of grinding your own flour as easy as possible. For a daily appliance the WonderMill is the most userfriendly and efficient. Check the price on Amazon. Electric Grain Mill Vs. Hand Powered.

Jet mill working principle

Jet mills operate in compressed air, gas or high pressure superheated steam. Jet mills have no moving parts, thereby eliminating contamination due to contact with external grinding media. It is also an ideal process to grind heatsensitive and waxy material because no attritional heat is generated. Jet mill works on fluid energy.

Barite Vertical Roller Mill

Advantages of Barite Vertical Roller Mill. 1. High grinding efficiency: save 20~30% power consumption compared with the ball mill. With the increasing of moisture content, it can save more and more electricity. 2. Strong drying capacity: dry and grind raw materials with moisture content as much as 15%. 3.

Raw Material DryingGrinding

Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (/sec above the ball charge), can handle moisture about 8%. Fully air swept mills (56M/sec) can dry up to 1214% moisture. Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in ...

Calcium Carbonate Grinding Mill

This series mills are mainly applied in the metallurgy, construction material, chemical, and mining, etc. The working principle is that by the shovel blade,calcium carbonate is put to the middle of calcium grinding roller and grinding ring, under the grinding pressure of calcium carbonate is crushed into powder, then under the action of the ...

Energy and Cost Comparisons of HPGRbased Circuits | E MJ

There was a discrepancy in the additional power required to reduce the final product size from 160 to 75 μm for SABC circuit and HPGRball mill circuit. The HPGRball mill circuit when grinding to 75 um compared to 160 um used an extra kWh/mt, but for the SABC circuit it only used an extra kWh/mt.

HCQ Reinforced Grinding Mill

Max feeding size: 2025mm. Capacity: /h. Fineness: (80400 mesh) HCQ Series Grinding Mill is a newly designed and developed mill, with more advanced technology than RSeries Pendulum Roller Mill. HCQ Series Grinding Mill has more scientific and reasonable configuration on main mill, classifier, blower, pipe system and feeder ...

How it Works: Crushers, Grinding Mills and Pulverizers ...

Jun 02, 2017 · Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it. As there is with crushers, there are many different types of grinding mills and pulverizers available. Ball, rod, pebble, autogenous and semiautogenous grinding mills all have a slightly inclined or horizontal rotating barrel or cylinder that mixes ...

Used Roller Mills, Roller Grinder | Used Impact Mill for ...

Supply power: 460 volt, 60Hz, 3ph, 110Amps. View Detail. ITEM: 16805 Model: . Used 24" Fluid Energy Pe Cyclojet 25 HP Grinder Mill 10557. 25 HP Westinghouse motor, 3520 rpm, 230/460 volt, 284t frame. It was made specifically for grinding of poly waxes for use in inks. The rotating 24" diameter wheel is not a classifier but actually part of ...

Colloid Mill: Operating Principles, components, Uses ...

Jul 05, 2020 · 4. Colloid mill is used for grinding, dispersing and homogenizing of ointment, cream, gels, and high viscous fluids in one operation. Advantages of Colloid Mills. 1. It has a wide range of use including comminution of slurry fluid materials. 2. No pressure is required for ionization. 3. The machine is simply constructed.

Used Equipment

Used Process Equipment Inventory. Equipment Company has one of the largest inventories of used process equipment and in the industry. We buy and sell equipment everyday so we know the value of equipment and know what type of equipment is in demand in the secondary marketplace. New items are added daily so our equipment ...

Grinding Circuit and Mill Safety

Aug 06, 2015 · Aug 06, 2015 · Electric motors are another dangerous area, around mills there is a lot of water. Water is being added to the mills, water is used to keep discharge screens clean. Water hoses are employed to wash floors, even the mills themselves. These larger motors require 4160 volts to operate. Therefore generate a lot of heat.

Quantifying the energy efficiency of fine grinding ...

As referred to earlier, the sizespecific energy calculation has typically been conducted at a marker size of 75 µm 5,6,7 because of the size reduction range of the equipment being assessed. However, in order to apply the technique to fine grinding devices such as stirred mills requires the use of a finer marker size.

Copyright © .CMichineAll rights reserved.خريطة الموقع