- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Reducing Cement PreHydration Could Improve Quality ...

Apr 21, 2021 · Similarly, GCP's quality improvers have helped improve mill production by up to 20 percent; early and longterm compressive strength by up to 30%; and helped lower energy consumption by about 25 percent, all without any loss of cement quality. "Our cement additives and waterreducing concrete admixtures reduce air pollution equivalent to ...

9 Ways to Improve Manufacturing Efficiency

12/12/2017 · How to Improve Manufacturing Efficiency. 1. Don't Waste Material. Waste is a broad term, and can refer to materials, energy, manhours or space. One of the biggest and most expensive kinds of waste is material waste. Here are a few ideas for reducing it: Focus on design. The best way to reduce material waste is to use less material from the ...

Vertical Roller Mill Parts

Vertical mill gives optimum grinding performance when grinding rollers and tables are in good condition, properly aligned and preloaded. Vertical Mill Tires and Tables. Rollers tyres and tables are main grinding elements in the vertical mill. As the grinding elements wear, the grinding efficiency of the vertical mill .

Sustainable grinding with FCB Horomill ...

The mill produces optimumquality, highresistance cement with a lower Blaine, and enables an exceptionally high cement/clinker ratio. The FCB Horomill® helps cement producers reach sustainability goals through: The lowest energy consumption on the market (3065% energy savings compared to ball mills, and 1020% compared to vertical roller mills)

how improve cement mill effeciency

increasing of production efficiency of cement mill How Improve Cement Mill Effeciency Efficiency Cement Ball Mill apeda Five Steps to Increase Ball Mill Efficiency College Essays wang Jul 4 2012 Cement ball mill is a new energysaving grinding equipment designed by It not only improves the productivity and crushing ration but also .

4 factors that affect milling machining accuracy ...

19/04/2016 · Each mechanical devices are manufactured by a variety of components constituted,components stiffness impact milling machining accuracy is major factors of affecting milling components stiffness is joint surface contact deformation, friction influence,low rigidity parts and gaps. You may be interesting in ' Remove Burrs of Machined ...

Cement | Magotteaux

To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms. With more than 7,100 tube mills equipped all over the world, you will benefit from the best experience in the cement industry. Our focus: reducing energy .

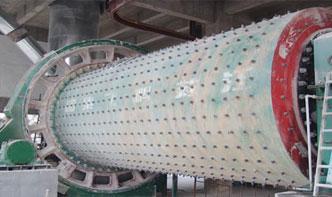

How to Improve the Working efficiency of Ball Mill?

Nov 25, 2013 · 3. Raw material of ball mill. The raw material which can increase the weight of the ball mill will also increase the inertia of Ball mill which will also improve the efficiency. 4. Electric current. The flow amount of electric current is the energy of ball mill. If the flow amount of current increase, the efficiency will also be improved.

8 Easy Ways to Improve Construction Efficiency on Your Project

10/08/2017 · For example, a supervisor could use his new skills to guide workers in a more efficient way of installing steel beams, enabling you to get the work done sooner and move on to the next phase. 6. Improve your communiion (via Todd Van Hoosear) If you aren't communiing with your team, that's a recipe for big losses in efficiency.

Google Scholar

Google Scholar provides a simple way to broadly search for scholarly literature. Search across a wide variety of disciplines and sources: articles, theses, books, abstracts and court opinions.

Cement Grinding Aids Market to Surpass US 5, Million ...

Jul 07, 2020 · The main purpose of it is to reduce the energy required to grind the clinker into a given fineness and therefore, increase the efficiency of the cement mill. These factors are expected to boost ...

The cement industry at a turning point: A path toward ...

01/12/2015 · In the cement industry, however, this link is weak. The industry's record of value creation is spotty, with ROIC levels roughly equal to the cost of capital, at around 9 percent. Behind the lackluster ROIC, two drivers stand out: high goodwill (seen in the low tangible capital ratio) and inadequate capital efficiency. Call it bad timing.

Ball charges calculators

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modifiion of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modifiion of the ball charge in order to improve the mill efficiency:

(PDF) Energy Audit in Cement Industry (1500 tpd | IJSTE ...

Koroneos et al. [2] contented that the exergy analysis of a cement plant was found to be a method of minimizing the energy cost and environmental effects. Zafer et al. [3] have analyzed the energy and exergy balance of the raw mill of a cement plant and observed that there is a potential for enhancing the exergy utilization.

Cement Grinding Aids |

Cement Raw Mill Grinding Aid (RMGA) We produce high quality product of Cement Raw Mill Grinding Aids to help achieving high level of raw material fineness in raw mill. RMGA will improve the grinding efficiency (increase output) and reduce energy consumption of raw mill.

EnergyEfficient Technologies in Cement Grinding | IntechOpen

Oct 05, 2016 · 1. Introduction. Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns. In recent years, the production of composite cements has ...

How to Increase the RValue of a Concrete Block Wall ...

19/12/2018 · How to Increase the RValue of a Concrete Block Wall. A wall's thermal resistance, or its Rvalue, is its ability to slow the transfer of heat from one side to the other. Concrete block makes a ...

Msds Cement Grinding Aid

Cement grinding aids for cement production and grinding aid The beneficial effects of scientific and rational use of cement grinding aids on cement production 1 Improve grinding efficiency increase bench production and reduce power consumption This is the most direct effect of using cement grinding. View Details Send Enquiry

Grinding Aids for cementTerm Paper

May 11, 2015 · Increase of the cement utilization demands for higher production efficiency and ultimately low production cost. The efficiency of the cement production depends greatly upon the efficiency of a grinding mill which consumes 6070% of the total electricity consumption of the cement .

PERFORMING A CEMENT PLANT OPERATIONS AUDIT

To improve the production process, increase the productivity, decrease energy consumption of the plant. Thermal energy is related to the pyro processing system. For a clinker production of 1 million tons per year, the savings of 10 kcal/kgcl would result in an annual savings of approximately 92,000.

Factors Influencing The Grinding Efficiency | Mill ...

Improve product quality * Optimize cement particle size distribution * Improve cement strengths 1, 2 and 28 days Way of use: GA sprinkled on fresh feed (diluted with water) In general .01 % to .08% are added (250 gr/t) Quantity (and efficiency) increase with Blaine fineness Slegten grinding course 21 Factors influencing the grinding efficiency ...

(PDF) The improvement of mill throughput using ...

Opportunities exist at cement plants to improve energy efficiency while maintaining or enhancing productivity. ... which can increase the cement mill throughput and decrease the energy consumption ...

TDA®

Feb 05, 2021 · Increased grinding efficiency resulting in increased mill output, higher cement fineness and reduced unit power input and grinding costs. Increased workability (flow) of cement mortars and concretes. Increased cement flowability for reduced pack set or "silo set" of cements, resulting in lower handling costs and reduced waste.

Energy efficient cement ball mill from FL

With more than 4000 references worldwide, the FL ball mill is proven to do just that. What we offer. The ultimate ball mill – with flexibility built in. You can't optimise cement grinding with a onesizefitsall solution. That's why our ball mills are designed to adapt to your requirements, with a high degree of flexibility built in.

Copyright © .CMichineAll rights reserved.خريطة الموقع