- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Current Trends in Milling Technology

22/09/2011 · However, the ball milling process is long and tedious, relying on ceramic balls or cylinders in a tumbling vessel to crush the media into a powder. ... than 100 microns in size. Additionally, the media is very susceptible to temperatures of 100 degrees Fahrenheit or higher. At these temperatures the powder begins to lose its bioactivity.

High vibrations on a ball mill | AMP Maintenance Forums

21/01/2011 · High vibrations on a ball mill. Hello everyone, I have a problem with high levels of vibration at the supports of the pinion (fixed and floating bearings) of the cement ball mill. The kinemantic scheme with the measurement loions and several representative spectra and timewaves are in the attched file. The dominant vibrations are in the ...

High Temperature in Slide Shoe Bearings

Look for manuals and see working range parameters for oil temp, oil pressure, initial high pump pressure, low pressure pump oil flow and speed, and then observe those in operation. Once the mill is stopped for regular maintenance check with a portable thermometer the slide shoe from the outside, look for temperature highest point, look for ...

Factors Affecting the Efficiency of Ball Mill Essay

02/04/2012 · The normal temperature of ball mill is high and there are many reasons, such as friction between materials and grinding body and impact between grinding body and liner plate. The temperature of grinding materials is too high and the heat loss after grinding is less. Ventilation effect in production is not good because of technological limitations.

Ball Mill Campaign – Royal Duyvis Wiener

Our Ball Mill's compact vessel with comparable amount of balls, results in a milling chamber with almost no deadspace. Less product in the ball mill during grinding leads to a reduction of waste during product changes. Making this generation of ball mills the most effective so far.

Temperature Progression In A Mixer Ball Mill Ball Mill

Apr 22, 2016 McKissic et al. observed a temperature of 50 C after 1 h milling in a Spex mixer mill and Takacs and McHenry reported milling ball temperatures of 66 C [12, 13]. Comparably higher temperatures can be reached in planetary ball mills (PBMs), where temperatures from 60 to 600 C can be measured, depending on the type of PBM, the ...

Decoupling the Arrhenius equation via mechanochemistry ...

30/05/2017 · According to reports in the literature, scientists have reported temperature ranges as low as 40 °C in vibratory mills to as high as 600 °C in planetary mills. 31,40,41 However, these reports measured the temperature of the ball and/or vial after the reaction concluded, which doesn't provide information on the temperature of the reaction at ...

Emax: High Energy Ball Mill from RETSCH : Quote, RFQ ...

The E max is a new kind of ball mill specifically designed for high energy milling. The unique combination of high impact and friction produces ultrafine particles in a very short amount of time. The optimized jar design and an unrivaled speed of 2000 min1 produces the high energy input. Thanks to the new cooling system with water, the high energy input is efficiently employed for the ...

Ball Mill Trunnion Bearing Lube System

10/01/2016 · On a 11'6" x 22'0" Ball Mill, the trunnion bearing lubriion system provides continuous low pressure flood oil for cooling and lubriion of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor ...

Ball Mills – Scientific Solutions

Ball Mill's are a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. They work on the principle of impact and attrition. Planetary ball mills are smaller than common ball mills and mainly used in .

Cement grinding Vertical roller mills versus ball mills

The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball mill the comminution takes place by impact and attrition. The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the ...

The Reason of Ball Mill's Uneven Discharging

22/02/2021 · Secondly, the high temperature of the inside of ball mill causes a "bag". If grinding temperature is too high, we should control the grinding material temperature, the water spray in mill, and increase the grinding body drench water, strengthen the inside ventilation, join the grinding material, and reduce the ratio of feeding. The two ...

Optimization of the high energy ballmilling: Modeling and ...

more difficult motion of balls as well as powders inside the milling vial and hence decrement of the mill's power. φ can be calculated from the following equation: φ ¼ nV b þ Vp Vt ¼ n 4=3πðÞd b=2 3 þ mp=ρp πr2 vHv ð2Þ where V b is the volume of each ball, V p is the volume of powders used, m p is the mass of the powders used, V t ...

Decoupling the Arrhenius equation via mechanochemistry

milling On the other hand, vibrational mills use high frequency oscillations/shakings of a reaction vial, o en with just a single ball, to induce chemistry. 15,27,29–34 The vial and balls

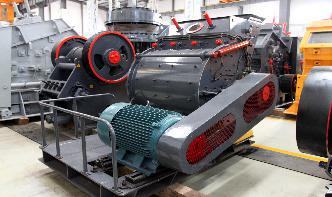

BALL MILLS

BALL MILLS. Very low cost of operation and maintenance; High quality production with high capacity; Very simple conditions for maintenance; Ball mills are the best and most effective method for crushing and powdering a variety of dry and wet materials, including minerals, types of building materials, sand and cement, lime and ceramics, and many other materials.

Ceramic Ball Mill In Ecologic Use | Fote Machinery

Advantages of ceramic balls (Aluminum ball) Ceramic mill balls are white balls with a diameter from mm to 120 mm. Their composition contains 90% of aluminum. Therefore, ceramic balls are also called aluminum balls. With properties of higher density and greater gravity, ceramic balls .

Copyright © .CMichineAll rights reserved.خريطة الموقع