- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Coal Mills for Cement Plants | Loesche

Coal Mills for Cement Plants. Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special versions are available with characteristics that meet special safety regulation or output control requirements. REFERENCES PLANT SIZES 3D PLANT ...

Working Of Vertical Coal Mill For Cement Plant For Sale

Working Of Vertical Coal Mill For Cement Plant For Sale. For additional vertical coal mill options check under Vertical Roller Mills our We can currently offer for sale a low hour secondhand Kovako D130S Dock Mobile Shipunloader This is a pneumatic unloader suitable for unloading cement and other powdered materials Nominal capacity is 195 tons per hour and it can unload ships up to 12000 dwt size

Industries – Pronamic

Pronamic® parts and services are approved and recommended by Loesche for all their vertical roller mills in the cement, steel, coal, mineral and ore industries. That includes parts for new mills, as well as parts and services for the aftersales market. Pronamic® services are available in the workshop and insitu for most types of vertical roller mills. We extend the Pronamic® parts ...

Quality Vertical Cement Mill Cement Ball Mill factory ...

Cement Clinker Grinding Mill, Coal Ball Mill For Manufacture Industries; Strong Drying Capacity Vertical Cement Mill Low Noise 100mm Max Feeding Size; 18KW Cement Ball Mill For Cement Grinding High Milling Efficiency Steadily Running ; 125kw Vrm Vertical Cement Mill For Cement Clinker Grinding Station; Chemical Industry 200T/H Vrm Cement Mill For Raw Coal; Water Slag Coal .

Roller Mill Components – Cement Americas

· Roller Mill Components. Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works. In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker. These mills offer a high throughput rate and ...

Cement

Below is list of our running items in cement industry. Crusher Spares Lime Stone / Coal / Clinker Crusher Spares Mining Crusher Spares. Mill Spares Vertical Roller Mill (VRM) Spares Ball Mill spares Grinding Media . Kiln and Other Spares Kiln/cooler spares, pre heater cyclone spares Stacker Wheels. Blow Bars. Hammers. Mill Liners. Slotted Liners. Tip Casting. Dip Tube Set. Dam Rings. Kiln ...

coal parameters for cement mill

Coal parameters for cement mill Henan Mining Machinery. Coal parameters for cement mill Related parameters of vertical mill The rotation speed of the mill determines the residence time of the material on the grinding disc and must be balanced with the grinding speed Different types of mill speeds are different but the centrifugal force requirements of the material are the same For cement and

vertical mill|coal vertical rooler mill|slag vertical ...

ADD: Pengfei Industrial Park of Hai'an County, Nantong City, Jiangsu Province, China CONTACT PERSON: TEL: WEBSITE: EMAIL: wqgpf2009

The important role of vertical roller mills in the cement ...

The important role of vertical roller mills in the cement industry Companies in the global cement industry are facing major challenges: If they are to improve productivity while simultaneously decreasing costs, they need highperformance products that are also energyefficient and offer maximum availability and flexibility. These products also need to comply with environmental regulations ...

vertical coal mill for cement industry

Vertical Coal Mill Operation In Cement Industry. Cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindingver the last three decades the vertical roller mill has become the preferred mill for grinding of raw materialshe grinding.

Development of vertical mills in the cement production ...

Consult Xinxiang Great Wall Machinery Co., Ltd's Development of vertical mills in the cement production industry brochure on DirectIndustry. Page: 1/2

Vertical Roller Mill VS Roller Press in Cement Industry

Tube mill has been used as the main grinding equipment in the cement industry for a long time, and it is still widely used because of its simple structure, easy operation, and low price. However, the energy utilization rate of tube mills is only 2% ~ 20%, which is very low. With the continuous development of grinding technology, there are two kinds of cement grinding equipment with lower ...

Cement Vertical Mill for sale

The vertical mill is divided into coal vertical mill, slag vertical mill and cement vertical mill according to the appliion. Cement vertical mill is pressurized by hydraulic system, and the pressure acts on the material between the grinding roller and the grinding disc to achieve the purpose of grinding, vertical High grinding efficiency, 2030% energy saving than ball mill; can ...

petcoke

· India: Wonder Cement has ordered its eighth vertical roller mill from Germanybased Gebr. Pfeiffer. A MPS 3070 BK type mill has been selected for grinding petroleum coke and coal. The throughput rate for pure petcoke grinding will be 40t/hr with a product fineness of 2% R 90µm. The mill will be equipped with an SLS 2900 BK type classifier. Due to the high abrasiveness of Indian coal, the mill ...

Coal for cement: Present and future trends

· Next, in November 2014, Titan Cement ordered a Gebr. Pfeiffer SE type MPS 2800 BK vertical roller mill for coal grinding, to be set up at line 1 at its Beni Suef plant. In January 2015, Suez Cement, Italcementi's Egyptian arm, said that it would spend US84m during the year to convert its Helwan and Tourah 2 cement plants to use coal. "We finished converting two plants in 2014 .

Coal Mill in Cement Plant | Vertical Roller Mill Air ...

Coal mill is also called coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are airswept ball mill and vertical roller mill.. At present, most cement plants use coal as .

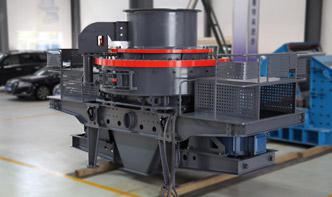

Working Of Vertical Coal Mill For Cement Plant Photos

It is widely used in Cement Plant Steel Mill Thermal Power Plant electricity field metallurgy sector building material industry chemical industry etc It is an ideal device that integrates crushing drying grinding and grading conveying all together 1 Coal vertical roller mill can handle all types of coal Coal vertical roller mill . More Details. coal mill vertical roller mill Solution for ore ...

vertical coal mill for cement plant

Product Profile Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and ... Vertical Coal Mill Cement Machine Established in 1994, Jiangsu Pengfei Group Co., Ltd is a professional manufacturer of vertical coal mill in China.

vertical roller mill

· Egypt: Helwan Cement has ordered a vertical roller mill from Gebr. Pfeiffer to grind coal at one of its cement plants in Egypt. Delivery of the coal mill is scheduled for the end of 2016. The order was placed by Beijing Triumph International Engineering. The type MPS 3350 BK coal mill will have an installed gearbox power of 1050kW. It is ...

Gearbox For Cement Industry | Elecon

Meet ELECON, who Epitomizes cutting edges technology and path breaking innovation that have made us supplier of choice for cement companies. Backed by a proven track record, spanning well over six decades and driven by unwavering excellence, Elecon is all set to meet the changing requirements of the cement industry and churn out technologically superior product from time to time.

Cement mill

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement grinding Vertical roller mills versus ball mills

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined ...

Advanced process control for the cement industry

platform in the cement industry. It is based on the latest developments Fuzzy Logic and Modelbased Predictive Control. The control strategies in ECS/ProcessExpert are based on four decades of experience in cement control and optimization projects. Operator Limits Advanced Process Control Operator vs computerbased decisions Vertical Roller Mill Appliion Page 10 Kiln Cooler Appliion ...

Copyright © .CMichineAll rights reserved.خريطة الموقع