- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

InPlant Training Report Presentation

Jul 18, 2016 · 9. Nitrogen/ Argon purging on whole process time for stirring of the molten metal promote homogenization.(After 20minutes using of Argon should be start in case of purging) 14. Slag Analysis Induction Furnace Slag LRF Slag SiO2: 6080% MnO: 520% FeO: 1015% Al2O3: 15% CaO: 56% SiO2: 1315% FeO: % MgO: 67% Al2O3: 20% 15.

Electric Arc Furnace Steelmaking

The importance of electric arc furnace steelmaking is evident from the escalated world production seen in steel industry. This book presents systematic and complete details on the current state of knowledge about metallurgical processes carried out in the electric arc furnace. It includes principles of construction of electric arc furnaces, applied construction solutions, and their operations ...

Rotary Reverberatory Furnace (Anode Furnace)Pyrometallurgy

Description. Rotary reverberatory furnace, also named as anode furnace, is especially used to treat copper scrap (Cu 92% and above) to get copper anode (Cu 99%), which can be further purified by electrorefining to produce % Cu hode. The copper hode can be processed by upward casting machine to standard copper rod.

Vacuum Induction Melting Furnace

The vacuum induction melting furnace process can accurately control the chemical composition of the alloy, for the reactive elements containing and oxygen and nitrogen affinity Al, Ti, B, Zr, etc., can be controlled in a very small range. The low melting point and volatile metal impurities, such as Pb, Bi, Sn, Sb, etc. can be removed by ...

Controlling Carbon, Sulfur and Metal Penetration of ...

Nov 01, 2000 · Coreless induction furnace refractory linings (Fig. 1) have two common characteristics that drive gas and metal penetration. The first is porosity (in the range of 1525%). It is comprised of closed pores and cracks in the grain and interconnected closedpore cells as a .

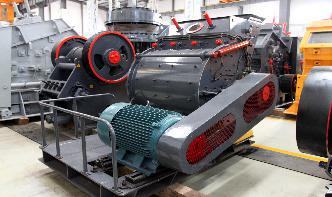

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Learn Everything About Types of Industrial Furnaces

Induction furnaces operate by a process called electromagnetic induction where an electric current is passed through a metal coil creating a magnetic field where electrical resistance raises the temperature of the metal to be processed. To be able to withstand longterm use, induction furnaces are made of heatresistant materials.

Magnesia Brick, Magnesite Bricks, Magnesia Bricks ...

Magnesia Brick. The company uses highgrade magnesia and strict process to produce magnesium oxide content of more than 90%, with periclase crystalline phase mainly basic refractories. Magnesia brick has high refractoriness, good alkali resistance slag resistance, high load softening starting temperature, but poor thermal shock resistance.

Electric Arc Furnace: Definition, Types, Construction ...

Production of slag will be more in this process. heavy trucks are needed for scrap handling; Due to the presence of dynamic quality of the arc furnace load, power systems may require technical measures to maintain the quality of power. Appliions of Electric Arc Furnace: The appliions of Electric Arc Furnace are as follows.

crusing plant of steelslag

Oct 1, 2007 Electric Arc Furnace (EAF) slag from one of the steel plants in Western The steel slag after crushing is partly recycled through a sintering plant. to melting at a temperature of 1500C in a graphite lined induction furnace.

Suitability of Steel Making Slag as a Construction ...

Jul 16, 2021 · Slag Sample Crushing. The slag sample to be crushed was placed into a lowdensity polyethylene (LDPE) plastic bag with a zip closure. The bag was then placed inside another LDPE bag, and this process was repeated 5 times. The bags were used to make sure that parts of the slag sample did not get propelled out of the crushing area.

Project Report on CEMENT PLANT USING CLINKER (CRUSHING ...

CEMENT PLANT USING CLINKER (CRUSHING PLANT) Project Report Manufacturing Process Cost Investment Required. Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much more.

Induction Furnace Pusher, Electric Induction Furnace ...

BS Mechanical Works Offering Induction Furnace Pusher, Electric Induction Furnace, इंडक्शन भट्टी, Hydraulic Furnace Pusher in Sirhind, Punjab. ... Product Description. ... Our range of equipment is widely used in the crushing process of stone, slag.

China Induction Melting Furnace, Induction Melting Furnace ...

China Induction Melting Furnace manufacturers Select 2021 high quality Induction Melting Furnace products in best price from certified Chinese Boiler, Oil Boiler .

Slag Processing Plant Details

slag,iron furnace slag,slag processing,induction furnace ... JMD introduces the first eversuccessful slag crusher plant in used by reputed steel plants in India, JMD Crusher Plant is widely used for crushing especially slag ...

slag crushing induction

slag crushing process of induction furnace slag crushing process for recovering metal from inductAppliions News amp; Blog FAQ Contact About the Read More gt;gt; Feb 15, ; melting furnace slag has become an important branch of the description of induction furnace slag crushing process description of induction furnace .

Electric arc furnace

An electric arc furnace (EAF) is a furnace that heats charged material by means of an electric arc.. Industrial arc furnaces range in size from small units of approximately onetonne capacity (used in foundries for producing cast iron products) up to about 400tonne units used for secondary furnaces used in research laboratories and by dentists may have a capacity of only a .

What Do MetalRefining Furnace Operators Do (including ...

Jan 12, 2021 · On a daily basis, MetalRefining Furnace Operators inspect furnaces and equipment to loe defects and wear. They record production data, and maintain production logs.. A typical day for a MetalRefining Furnace Operator and Tender will also include: Observe air and temperature gauges or metal color and fluidity, and turn fuel valves or adjust controls to maintain required temperatures.

USA1

A method of recycling electronic waste and recovering valuable metal components from electronic waste which involves feeding electronic wastes such as cell phones, computers, pagers, personal data assistants, handheld global positioning devices, MP3 players, calculators, batteries, etc. into an induction furnace that is changed with a mass of liquid iron.

Pit Furnace Melter Job Description

Pit Furnace Melter Employee Duties Responsibilities 1) Controls gas, oil, coal, electricarc, or electric induction furnace to melt metal prior to casting. 2) Weighs out specified amounts of metal ingots scrap metal and charges metal into furnace by hand, using hoist, or by directing crane operator to charge furnace.

slag granulation process digram

flow chart description wet process cement in raw mill – Grinding ... Posted at: December 11, 2012 . ... raw mill loeshe operation flow digram[crusher and mill] ... Furnace slag crushing machine manufacturer in China Gold Ore Crusher. chinese technology for blast furnace slag granulation process; iron slag crushing .

Zinc Melting Cored Induction FurnacePyrometallurgy

The furnace is made up of furnace body and inductors. The furnace body includes furnace shell, frame and refractory lining, common service life 5 years. The inductor is composed of magnet yoke, induction coil, metal channel, refractory lining of melting channel. The lifetime of inductors determines the maintenance interval of an induction furnace.

Copyright © .CMichineAll rights reserved.خريطة الموقع